Are you curious why we came up with the Griffin Vane?

At Bohning, we pride ourselves on manufacturing products that solve problems for the archer. We saw how much time and energy Olympic recurve archers were spending re-fletching spin type vanes. Spin or “mylar” vanes aren’t advantageous when it comes to durability and convenience – if you’ve used them, this is not news to you. Properly and accurately fletching a mylar vane requires a significant amount of time, and given their fragility, you have to replace them a lot. Additionally, mylar vanes have significant drawbacks in crosswinds due to their surface area.

We knew that to solve the problems found in spin vanes, we needed to create a durable, lightweight, easy-to-install vane that would perform as well as or better than spin type vanes. We set these three measurable goals:

1. The new vane had to perform as well as or better than a mylar vane

2. It had to be way more durable

3. It had to be easier to fletch

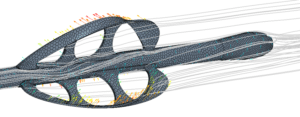

It took us a few years to get it right. Pairing up our engineers with an aerospace engineering firm, we began with several unique vane concepts, then conducted thousands of computer simulations before moving to lab prototypes to identify the best ones.

An early Griffin concept that didn’t make the cut

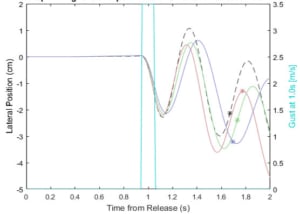

We tested things such as drag, side and lift forces, yaw and pitch, and the effect of variable and steady crosswinds coming at multiple speeds and directions. We used these test results to determine which vane design best minimized outside influences, such as lateral drift & over-correction. After selecting the best vane concepts, we proceeded to fine-tune the design. The next step was producing prototypes – not being a typical vane shape, this took some work.

Knowing materials impact flight, we also tested the best design concepts with dozens of different materials. After narrowing it down to a four workable materials, we began field testing.

For the field testing, we collaborated with archers all over the world – getting volunteers wasn’t difficult as archers love to tinker. Each archer was asked to shoot a minimum of 200 arrows in different weather conditions. They measured group sizes and provided input on each material. We eliminated two materials right away. In true Goldilocks fashion, the first prototype vane was too soft, it wouldn’t hold its shape, and the second was too hard. Though the harder vane’s performance was killer, it would crack upon impact with the target. Many iterations later, we identified a “sweet spot” material that is stiff enough to hold its shape and provide the best performance without cracking.

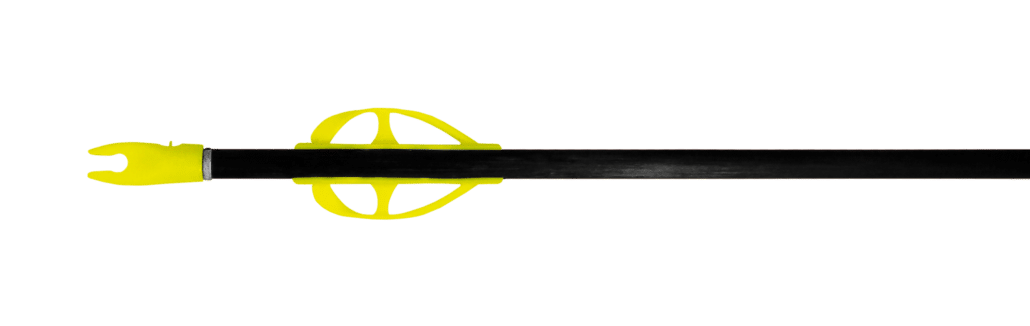

After making some tuning adjustments, archers saw their group sizes shrink when compared with mylar vanes, especially in windy scenarios. There are two main reasons for this. First, the “cut-out” surface prevents downrange wind drift, while the integrated right helical twist provides the required spin and steerage. Second, that same cut-out design keeps the grain weight to a minimum, making the back of the arrow weak and forgiving.

After checking off the “Durable” and “High-performing” boxes, it was on to the “Convenience” factor. We manufactured a clamp insert to make it easy for archers to fletch the Griffin Vane with a Pro Class style fletching jig (see images below). Because the helical is already built into the design of the Griffin vane, you can install the vane straight. The ability to use a fletching jig eliminates the need to line your arrows, and lets you quickly install vanes much more uniformly and accurately when you’re fletching at home or in the archery shop. We’re also working on a new Pro Class clamp specifically for the Griffin Vane that permits the vane to fit directly and securely into the clamp without having to use the insert – expect to see this available in late 2021. Like all Bohning vanes, the Griffin Vane is no-prep. We pre-prime the bases of our vanes, so we highly recommend that you NOT clean them as it will remove that primer.

We also know that, though it won’t happen very often if you’re shooting the Griffin Vanes, sometimes you have to re-fletch in the field. That’s why we designed the clamp insert so that you can use it without a jig when necessary. The clamp insert is stored right inside the Griffin packaging, which is very slim and fits nicely in your quiver. Each pack of Griffin Vanes comes with two clamp inserts. The final touch was designing the packaging to securely store the Griffin vanes.

We at the Bohning Company would like to extend a special thanks to our test staff who field-tested the Griffin Vane during all of these testing stages, it would not have been possible without your help.

“Hell YES! The Griffin Vanes are AWESOME in the wind! Even during the crazy east coast storms we’ve had, they performed perfectly. And they’re super durable – now when I’m on the road, I don’t have to spend my time re-fletching. Plus, the packaging is sweet – literally, it looks like a fancy chocolate bar, I love it.” – Lee Ford, Team USA